The Material Revolution in Bag Manufacturing

Modern brands demand more than durability—they want performance, sustainability, and differentiation.

One commercially proven innovation is 600D PVC-coated nylon, offering:

Enhanced abrasion resistance

Water repellency at competitive cost

Strong adaptability for custom designs

This makes it ideal for mid-to-high-end backpacks across multiple markets.

Huafang’s R&D Capabilities

Material Lab Collaboration

We work closely with material labs and fabric mills to test:

New coatings

Reinforced yarn structures

Eco-friendly alternatives

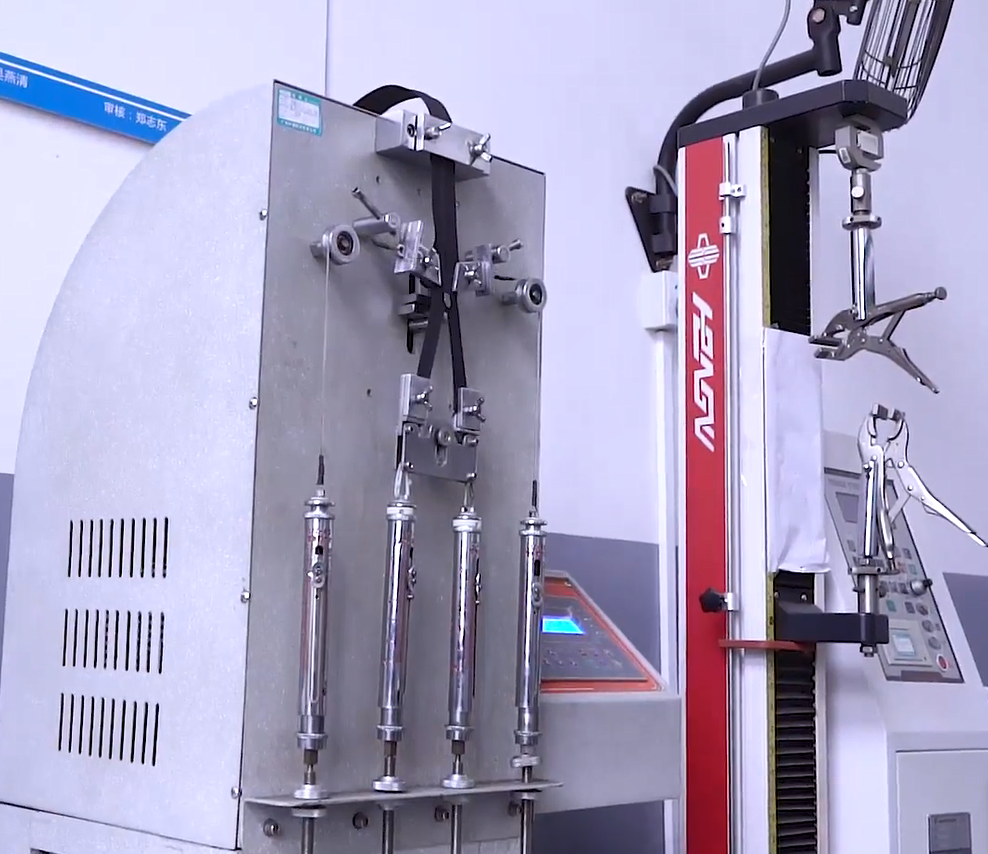

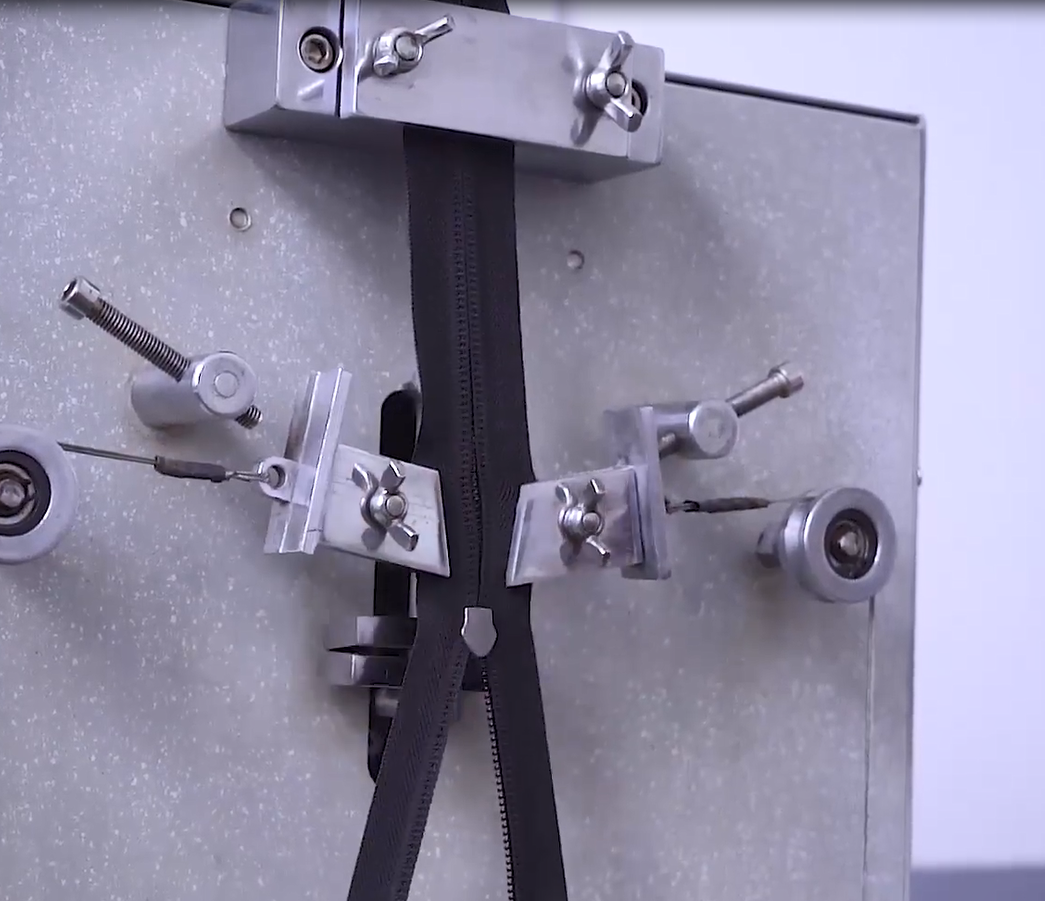

Testing & Compliance Process

Every new material goes through:

Strength & wear testing

Chemical compliance (REACH, CPSIA when applicable)

Real-use simulation

Application Scenarios

Outdoor brands: tear-resistant, waterproof fabrics

Gym & sports bags: odor-resistant linings, reinforced bases

Business laptop backpacks: structured panels with lightweight materials

Each solution balances cost efficiency and market acceptance.

Procurement Tip: Evaluating New Materials

Before committing, buyers should assess:

Incremental cost vs perceived customer value

Minimum order requirements

Long-term material availability

Innovation succeeds when technology aligns with market demand.