Sustainable Bag Sourcing: How to Verify Eco-Friendly Manufacturing at Scale

What Makes a Bag Truly Sustainable?

GRS vs RCS Certification: Key Differences

Why Major Brands Require GRS?

Eco-Friendly Material Selection Guide (By Bag Type)

Hidden Costs of Green Manufacturing

Conclusion

Sustainable Bag Sourcing: How to Verify Eco-Friendly Manufacturing at Scale

In today’s global market, more and more brands are seeking sustainable bag manufacturers and eco-friendly bag suppliers that can deliver large-scale production while ensuring environmental responsibility. This guide covers everything from material selection and production processes to certification standards, helping you make reliable decisions across your supply chain.

What Makes a Bag Truly Sustainable?

A truly sustainable bag is not only made from eco-friendly materials but also produced through low-carbon, efficient processes.

1. Material Dimension

RPET (Recycled PET) Fabrics: Made from recycled plastic bottles, waterproof, durable, and reduces plastic waste

Organic Cotton: Pesticide-free, biodegradable, ideal for shopping and casual bags

Recycled Leather: Substitutes traditional leather, minimizing livestock-related carbon footprint

2. Production Dimension

Centralized Low-Carbon Production: Large-scale factories reduce energy consumption compared to small workshops

Modern Production Lines: Efficient processes minimize waste and rework

3. Certification Dimension

GRS (Global Recycled Standard)

RCS (Recycled Claim Standard)

Certification ensures traceable raw materials, eco-friendly production, and compliance with international sustainability standards

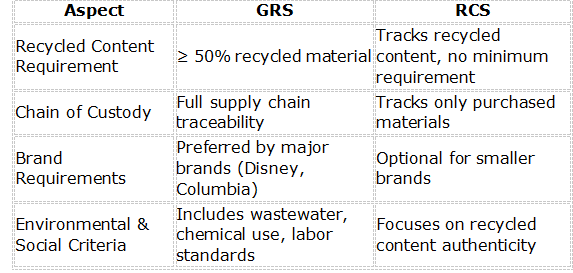

GRS vs RCS Certification: Key Differences

Why Major Brands Require GRS

Transparent, fully traceable supply chain

Compliance with international environmental and social responsibility standards

Our factory is certified by Disney , ensuring a reliable supply chain

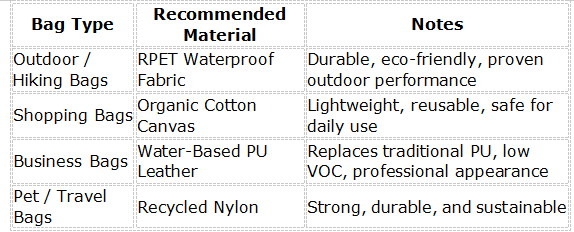

We have extensive experience applying eco-friendly materials across bag types, ensuring every batch meets functional and sustainability requirements.

Hidden Costs of Green Manufacturing

1. Factory Scale vs Carbon Footprint

Our 27,000㎡ centralized production facility reduces energy consumption through unified management

Compared to multiple small workshops, carbon emissions are significantly lower

2. Quality Control Reduces Waste

ISO9001-certified quality management system

Process control minimizes rework and defects

Ensures mass production matches samples while reducing material waste

Choosing sustainable manufacturing is not only an environmental commitment but also a long-term cost saver that strengthens brand credibility.

Conclusion

When selecting a sustainable bag supplier, it’s essential to consider materials, production processes, certification, and quality management across the entire supply chain.

We provide eco-friendly materials including RPET, organic cotton, and recycled leather, backed by GRS and RCS certification and experience with major brands like Disney and Columbia.

Our centralized, low-carbon production ensures large-scale, reliable, and sustainable bag sourcing.

Contact us today to start your eco-friendly bag sourcing journey!

Get in touch

If you have any questions about our products or services, feel free to reach out to the customer service team. We provide unique experiences for everyone involved with our brand. We offer preferential prices and high-quality products for you.

Recommended

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.