China offers the most reliable and advanced backpack production base worldwide.

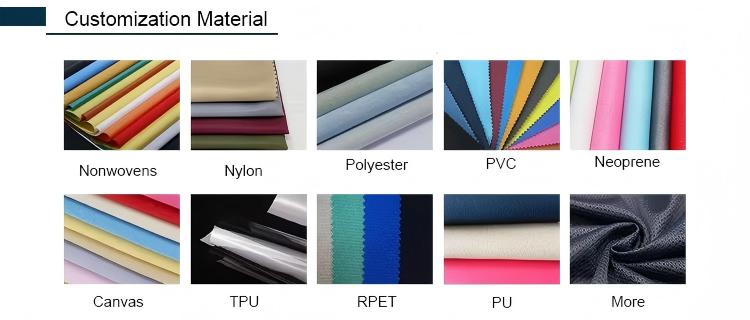

With a mature supply chain, skilled workforce, and access to diverse materials,

Chinese factories provide competitive pricing and high-quality manufacturing—making them preferred choice for global brands and startups alike.

Critical Factors to Consider When Selecting a Backpack Factory

1.Quality Control: Ensuring consistent product quality is one of the top concerns for international buyers. Not all factories maintain strict quality assurance systems.

2.Manufacturing Capabilities

Independent production facilities vs. outsourced production.

Factories with full in-house production can better control costs and timelines.

3.Certifications

ISO: Ensures high-quality management standards.

BSCI: Verifies social responsibility compliance.

OEKO-TEX and REACH for material safety and sustainability.

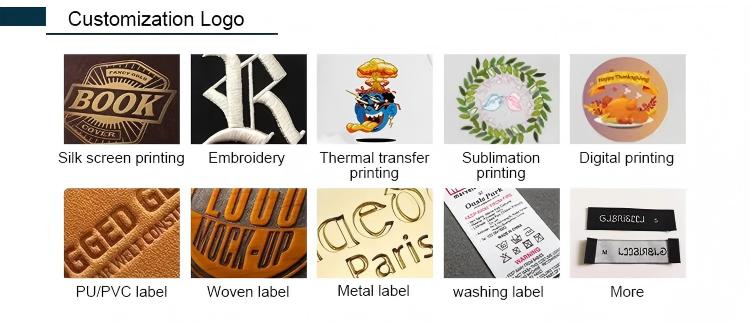

3.Customization Options

OEM/ODM services tailored to your brand requirements.

Logo printing, embroidery, and private label solutions.

4.MOQ Flexibility

Prioritize factories offering flexible order quantities.

For example, Huafang Bag Factory is known for lower MOQs, making it easier for startups to test the market.

Why Choose Huafang Bag Factory?

10+ Years of Backpack Manufacturing Experience: Trusted by global clients for over a decade.

Fully Independent Production: No intermediaries, ensuring cost savings.

Fast Sampling & Mass Production: Quick turnaround from design to shipment.

With the right backpack factory, you can achieve reliable production, strengthen your brand, and support long-term business growth. Partnering with a trusted and experienced

manufacturer like Huafang can give your brand a competitive edge in 2025 and beyond.